News and events from USTB about research, science and technology, social science, art,

faculty and staff, students life and issues happening all around the world.

Topics

Date

Views

On August 3rd, the selection results of the 2022 China Metallurgical Science and Technology Award were officially announced to the public. A total of 111 projects were commended, including 1 special prize, 23 first prizes, 29 second prizes, and 58 third prizes. Among them, USTB has won a total of 23 awards, including 1 special prize, 9 first prizes, 8 second prizes, and 5 third prizes. The number of special and first prizes of our university this year has reached a new high.

USTB paid a high value to the application of the Metallurgical Award, and the relevant achievements attracted the attention of the university leaders during the cultivation period. The project team sought perfection with the great support of each department and teaching and research unit under the meticulous organization of the scientific research management department. With the concerted efforts of all parties, the number and quality of the award-winning projects were high, which demonstrated USTB’s responsibility to advance the green and high-quality development of the iron and steel industry with practical actions. Those achievements also reflected USTBers’ dedication to the steel and iron industry of the country and polished USTB’s golden brand as the “Cradle of Iron and Steel Engineers”.

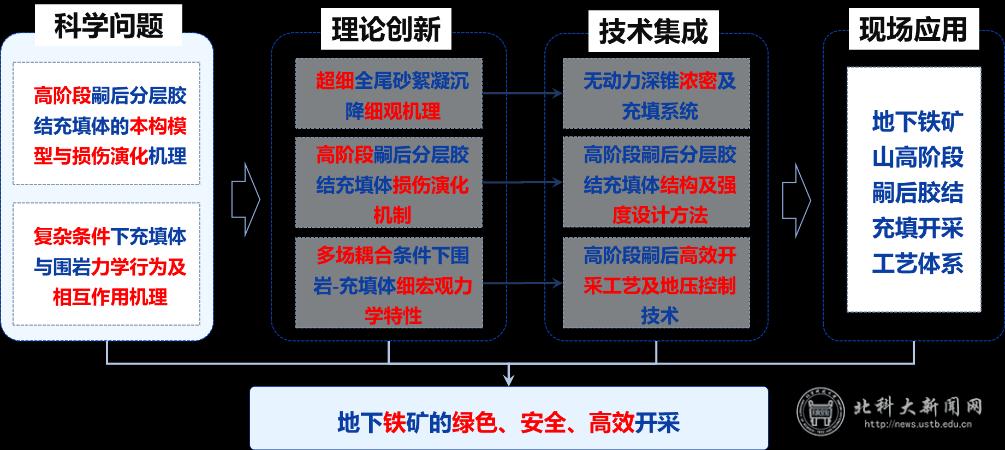

The Project “Theory and Application of High Stage Subsequent Cemented Filling in Underground Iron Mine”

The project “Theory and Application of High Stage Subsequent Cemented Filling in Underground Iron Mine” presided over by Associate Professor TAN Yuye won the first prize of the China Metallurgical Science and Technology Award. The project has carried out theoretical and technical application research in response to the problems of complex stope structure, increased ground pressure disaster risk, and increased demand for the strength of filling body caused by the high-stage and large-scale development of the subsequent filling method. Owing to the progress of theory and technology research of high stage subsequent cemented filling and mining in the mining industry, it realized the green, safe and efficient mining of iron ore resources, and promoted the green and sustainable coordinated development of resource development, environmental protection, economic benefits, and community construction, resulting in highly significant economic and social benefits.

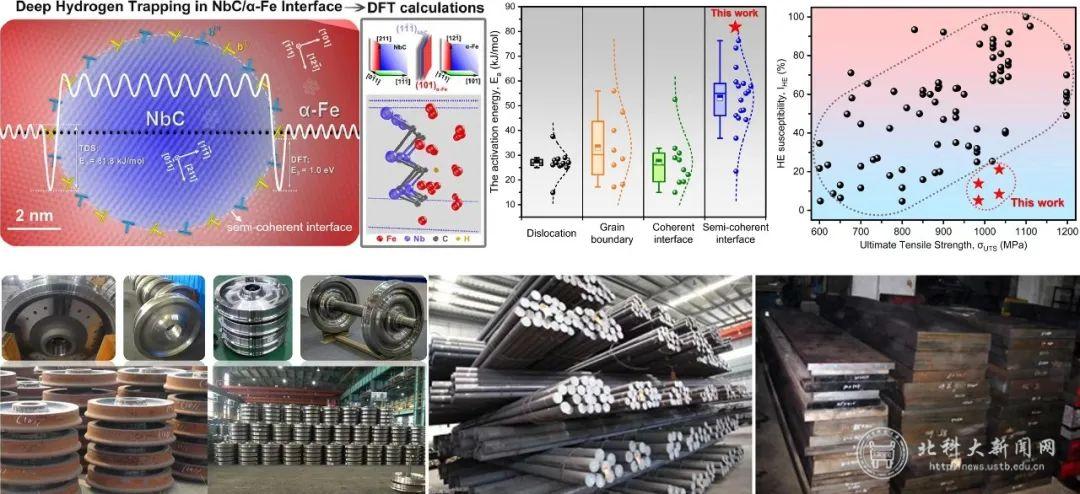

The Project “Basic Research and Engineering Application of Nano-phase Deep Hydrogen Trapping in High Strength-Toughness Steel”

The project “Basic Research and Engineering Application of Nano-phase Deep Hydrogen Trapping in High Strength-Toughness Steel” led by Professor PANG Xiaolu won the first prize. Through atomic-level observation, first-principles calculation, and other methods, the project revealed the atomic-level interaction mechanism between nanophase and hydrogen in high strength-toughness steel and established the idea of constructing nanophase as the main deep hydrogen trapping. Technically, through precise calculation and process control of multiple coupling thermodynamics, a large number of deep hydrogen trapping of dispersed distribution have been obtained, which ensured the stable mass production of high strength-toughness steel, hydrogen-damage-resistant heavy haul wheel steel, spring flat steel, and marine equipment steel. The project achievements have opened up the large-scale export of wheel steel to regions of highly-developed heavy-haul freight such as North America and Australia, which supported the major strategy of our country's railway going global. Besides, it eliminated shear cracks at the ends of high-strength spring flat steel and expanded overseas market share in Southeast Asia and other regions. Moreover, it solved the hydrogen embrittlement problem of high strength-toughness steel used in deep-sea oilfields and replaces imported products. The project realized the whole chain innovation from the theoretical source, and key technologies to core products, and generated huge social and economic benefits.

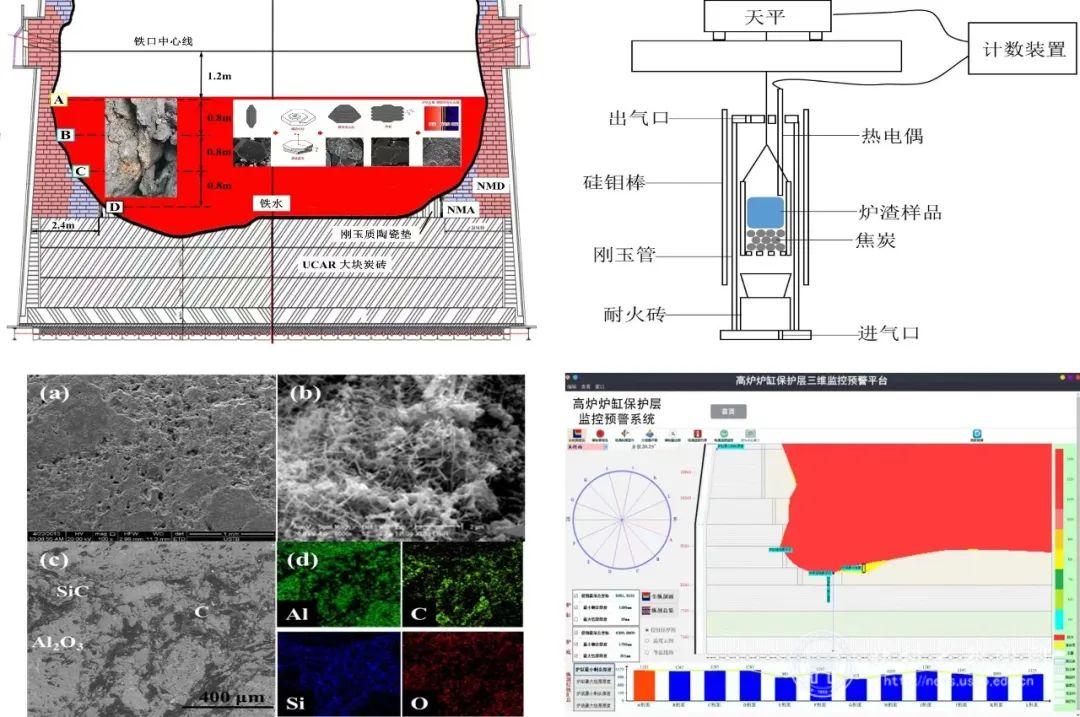

The Project “Basic Research and Engineering Application of Nano-phase Deep Hydrogen Trapping in High Strength-Toughness Steel”

The project “Key Technology R&D and Application of Self-repair Theory on Blast Furnace Safety and Long Campaign” presided over by Professor ZHANG Jianliang won the first prize. The core of the project was to build a permanent furnace lining. The safety and long campaign of the blast furnace was a systematic project integrating design, operation, maintenance, and monitoring with various influence factors. Over the past 20 years, the project team has established a theoretical system of the protective layer in blast furnace hearth, revealed the self-protection mechanism of graphite carbon precipitation on the hot surface of hearth refractory materials, and formed self-repair theory and key technology on blast furnace safety and long campaign with independent intellectual property rights based on the damage investigation and dissection research of more than 20 blast furnaces. The technology has been successfully applied to more than 10 blast furnaces in Wuhan Iron and Steel, Shagang Group, Taiyuan Iron and Steel, Shougang Group, and other enterprises, with many blast furnaces having a life span of more than 15 years. Such technology greatly reduced the fuel consumption and the cost of blast furnace protection, guaranteed the quality of molten iron, and thereupon achieved direct economic benefits amounted to more than 1.52 billion yuan.

The Project “Key Technologies and Equipment for Intelligent Management and Control of Long Products (Bars and Wires) Warehouse Areas”

The project “Key Technologies and Equipment for Intelligent Management and Control of Long Products (Bars and Wires) Warehouse Areas” led by Researcher WANG Xiaochen won the first prize of the China Metallurgical Science and Technology Award. Aiming at the technical bottleneck of the intelligent unmanned warehouse for long products, the project has cooperated with 9 units to carry out systematic theoretical and applied research on multi-source information sensing reconstruction, precise positioning control of machine vision, optimized scheduling of production logistics, and intelligent centralized control of long product warehouse areas. The project achievements have completed the first demonstration application of intelligent unmanned warehouses for high-speed wires and bars in Ma’anshan Iron and Steel and Yueyufeng Iron and Steel. It realized the leading role of localized independent technology of long product intelligent warehouses, filled the domestic gap, and provided key technologies that have been urgently needed by a large number of domestic long product manufacturers. The project achievements played an important supporting role in promoting the construction of long-product smart factories with less labor and high efficiency.

In addition, the project “Ouye Furnace Melting Reduction Ironmaking Process Technology Research” completed by Professor ZHANG Jianliang and others won the special prize. The project “Key Technology Development and Application of Continuous Casting of High-Aluminium Steel and Microalloyed Steel Slab” participated by Associate Professor YU Huixiang won the first prize. The project “R& D and Industrialization of Key Metallurgical Technology for High-quality Bearing Steel Production Based on Nonaluminum Deoxidation Process” participated by Professor BAO Yanping and others won the first prize. The project “Research and Application of Solutions to Intelligent Operation and Maintenance System for Equipment in Iron and Steel Industry” completed by Professor YANG Jianhong and others won the first prize. The project “R& D and Application of Key Technologies and Equipment of Large-diameter Thick-walled Stainless Steel Welded Pipes for Oil and Gas Transmission” participated by Associate Researcher XU Dong won the first prize. The project “Long-life Mechanism, Key Technology and Product Development of Special Steel for Basic Parts” completed by the School of Metallurgical and Ecological Engineering won the first prize.

Draft: GUO Qiuju

Revision: CHENG Mingyuan

Topics

Date

Views