News and events from USTB about research, science and technology, social science, art,

faculty and staff, students life and issues happening all around the world.

Topics

Date

Views

Recently, the Institute of Engineering Technology (IET) at the University of Science and Technology Beijing (USTB) signed a contract with Delong Steel Company Ltd. (Delong), for the development of a vision-based on-line measurement and control system for slab front-end bending on a 1250mm hot rolling line at Delong.

Following a series of installations of unmanned strip-rolling support technologies, IET has provided a complete series of solutions for automatic measurement and control of front-end bending in rough rolling, camber in rough rolling and deviation in finish rolling, which can significantly improve the unmanned intelligence level of a hot rolling production line and lay a foundation for a near fully-unmanned hot rolling process.

In this project, two sets of front-end bending measurement devices will be equipped at the entrance and exit of a rough rolling mill, which can support on-line detection, quality judgment and management, and automatic control for the front-end bending of a slab during the rough rolling process. This project is the final step in a series of asymmetric measurement and control supporting technologies for hot rolling, following the installation of the IET's camber measurement and control system for the rough rolling process in Shougang Jingtang United Iron & Steel Co., Ltd. and deviation measurement and control system for the finish rolling process in Maanshan Iron & Steel Company.

The front-end bending of slab is due to the difference in elongation in the thickness direction of the slab, causing either upward or downward bending. This defect will affect the service life of the rolling mill equipment, roller tables, guides and other equipment and reduce production efficiency. Being both difficult to detect and predict, previously controlling for slab front-end bending depends on artificial means, resulting in an unstable finished quality of the slab.

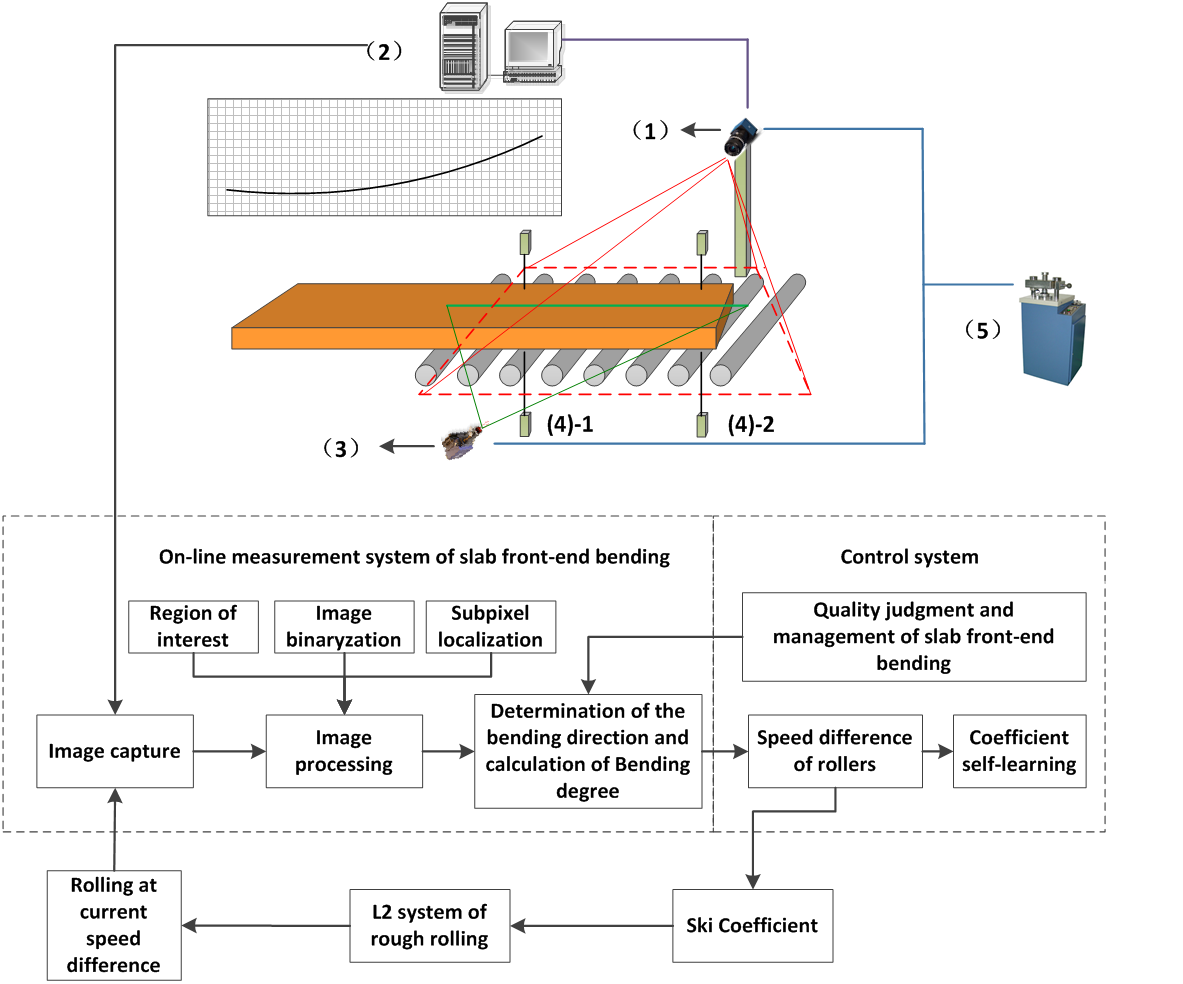

The measurement and control system of the slab front-end bending by IET has the following characteristics:

1) Use of a CCD camera to take pictures of the slab;

2) Providing accurate identification of slab front-end bending throughout all passes of the slab;

3) Real-time display of measurement results, online quality judgment and defects warnings;

4) The automatic control of front-end bending based on a mechanism model and data-driven model.

After the system is brought online, it will further improve the quality stability of hot rolling products and improve the automation capacity and unmanned intelligence level of Delong rolling mills.

At present, the design and processing of the hardware system have been completed. In the next step, the field installation and system commissioning of the equipment will be carried out, and the on-line application will be available in June 2020.

1- CCD Camera 2- Server 3- Line structured laser 4- position sensor 5- Water cooler

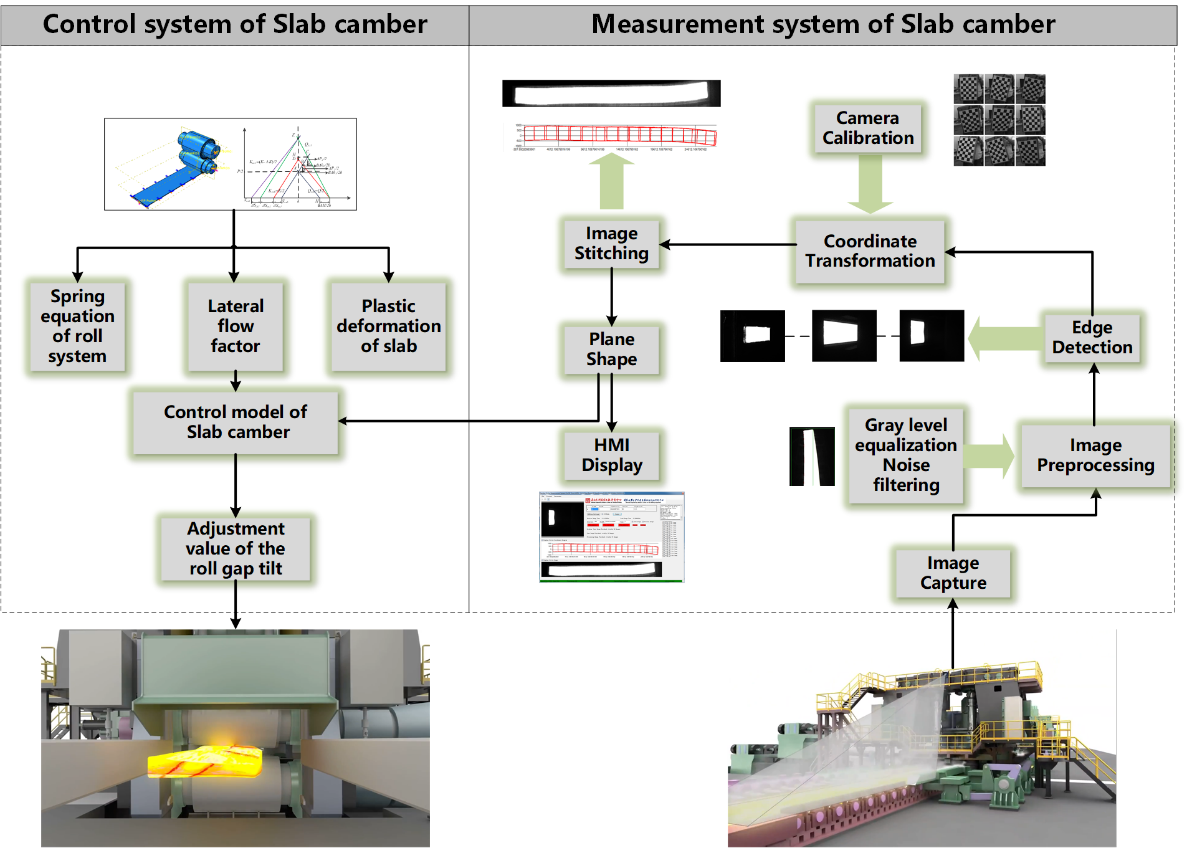

Figure 2 Flow chart of on-line measurement and control system for slab camber in rough rolling

Topics

Date

Views