USTB is committed to building itself into a high-level research-oriented university

which attaches importance to novel scientific research and promotes independent innovation.

“Technical Support Base for Prevention and Control of Major Accidents in Metal Smelting” (hereinafter called the "base") is a national safety supervision and monitoring technology support project in the Ministry of Emergency Management's "Plan for the Construction of Supervision and Monitoring Capacity of Safety Production Supervision Departments and Coal Mine Safety Supervision Institutions (2016-2020)" (General Safety Supervision Planning [2017] No. 70). The construction of the base provides all-round technical support for the safety production of metallurgical industry. It is of great significance to improve the technical support system of supervision and monitoring, significantly improve the scientificity, accuracy and objective of the supervision and monitoring measures and means of metal smelting major accidents, enhance the level and ability of enterprise safety production, and eliminate the major economic losses caused by major safety accidents.

The base was approved by the National Development and Reform Commission (Development and Reform Investment [2021]557), and built by University of Science and Technology Beijing and China Nonferrous Engineering Co., Ltd. The total investment of the base is 492.67 million yuan, of which the central budget is 468.05 million yuan, and the self-raised funds are 24.62 million yuan. The central budget funding is 410.59 million RMB for University of Science and Technology Beijing and 82.08 million RMB for China Nonferrous Engineering Co., Ltd.

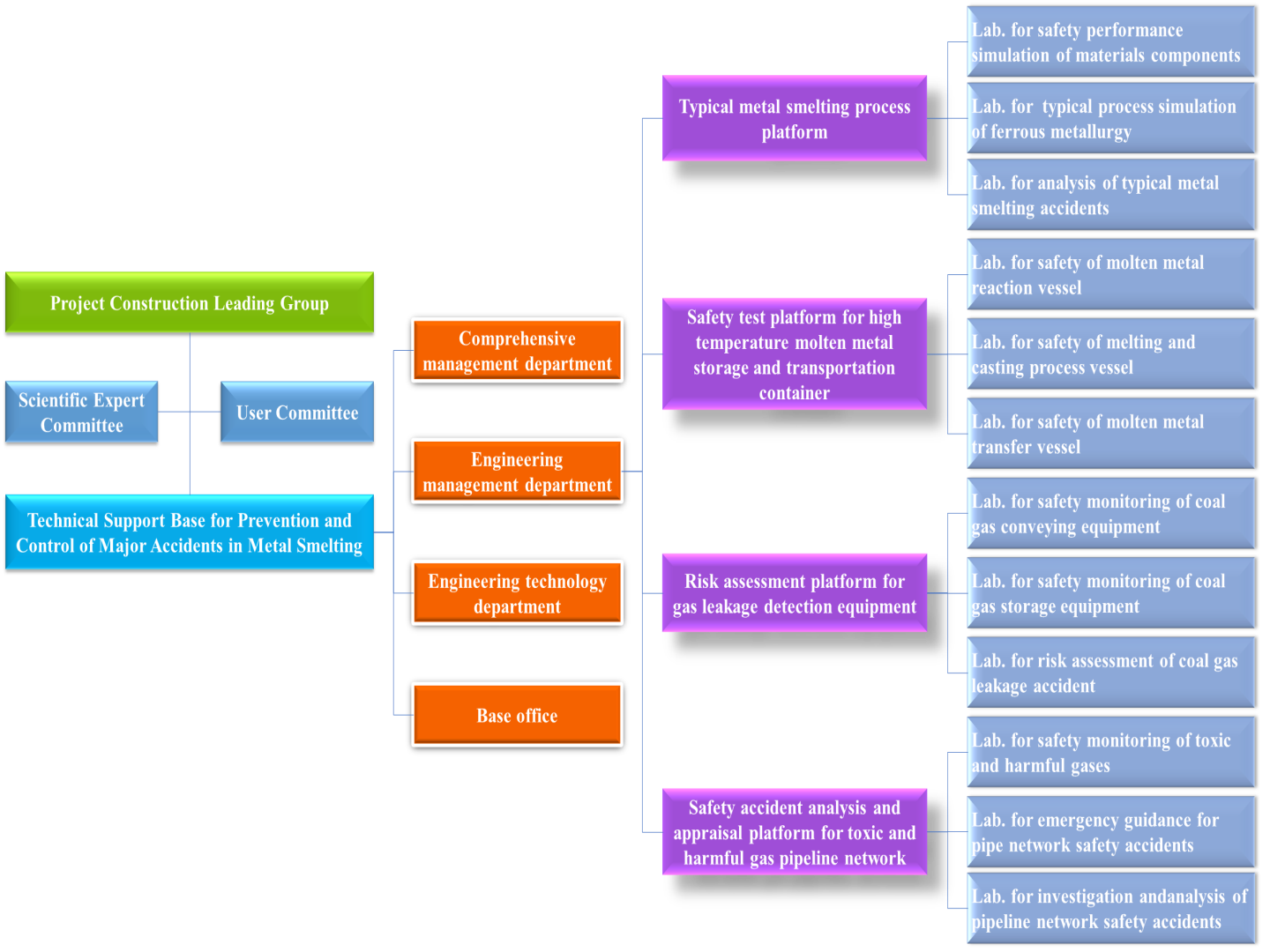

The construction of the base includes 14 professional research laboratories in four platforms, including "Typical metal smelting process simulation platform", "Safety test platform for high temperature molten metal storage and transportation container", "Risk assessment platform for gas leakage detection equipment" and "Safety accident analysis and appraisal platform for toxic and harmful gas pipeline network", among which USTB is responsible for the construction of 11 research laboratories and typical metal smelting accident analysis research laboratory (Ferrous sub-center) (Figure 1).

After the completion of the base, the safety conditions demonstration capability of new equipment, new materials and key technologies in the field of metal smelting reaches more than 90%. The ability to support the prevention and control of heavy accidents such as spattering, leakage and explosion accidents during the operation of high temperature incorporated metal containers reaches more than 95%. The research and development of core emergency rescue technology and key emergency rescue equipment for typical major metal smelting production accidents have reached the international advanced level.