USTB is committed to building itself into a high-level research-oriented university

which attaches importance to novel scientific research and promotes independent innovation.

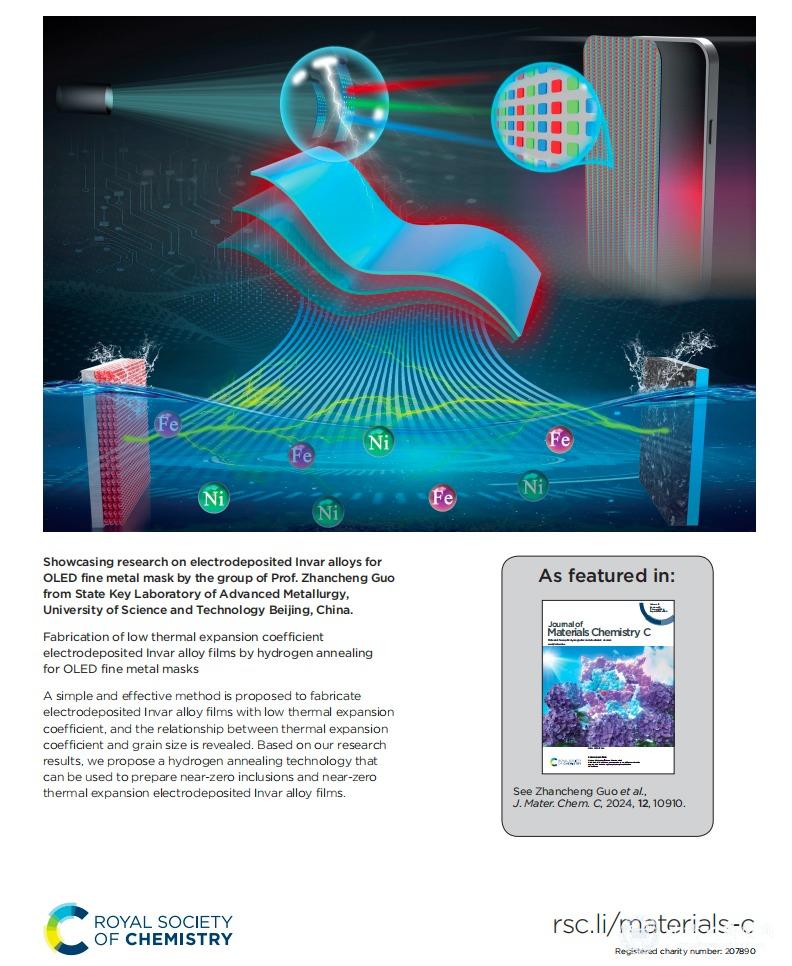

Beijing, July 29, 2024 – A research team led by Professor Zhancheng Guo from the State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, has achieved a major breakthrough in the development of fine metal mask (FMM) materials for OLED displays. Their work, which provides key technological advances in fabricating near-zero expansion Invar alloy films, was recently published on the cover of Journal of Materials Chemistry C (Royal Society of Chemistry).

Addressing OLED Industry Challenges

OLED displays, widely used in high-definition smartphones and TVs, rely on fine metal masks to precisely deposit organic light-emitting materials. To meet industry requirements, FMMs must maintain micro-scale dimensional accuracy at operating temperatures, with edge roughness below one micron and thermal expansion coefficients less than 1.5 × 10⁻⁶. However, conventional Invar alloy masks have struggled to meet these stringent demands due to microstructural inhomogeneity and processing limitations.

Innovative Electrodeposition Method

To overcome these challenges, Guo’s team developed an electrodeposition and hydrogen annealing technique that effectively controls impurity levels, grain size, and inclusion formation. By refining process parameters over more than five years of research, the team succeeded in producing near-zero expansion Invar alloy films with uniform microstructure and exceptionally low thermal expansion coefficients.

This innovative approach enables stable preparation of Invar alloy films with edge roughness below one micron—meeting the global benchmark for OLED mask performance. Notably, the electrodeposited films achieved a thermal expansion coefficient as low as 1 × 10⁻⁶, setting a new standard for high-precision applications.

International Recognition

The research was prominently featured by the Royal Society of Chemistry, highlighting its significance for next-generation OLED manufacturing. The paper, titled “Fabrication of low thermal expansion coefficient electrodeposited Invar alloy films by hydrogen annealing for OLED fine metal masks” (DOI: 10.1039/D4TC00910A), showcases how fundamental advances in alloy processing can address pressing technological bottlenecks in display technologies.